THE BEGINNING OF FISH PROCESSING FACTORIES

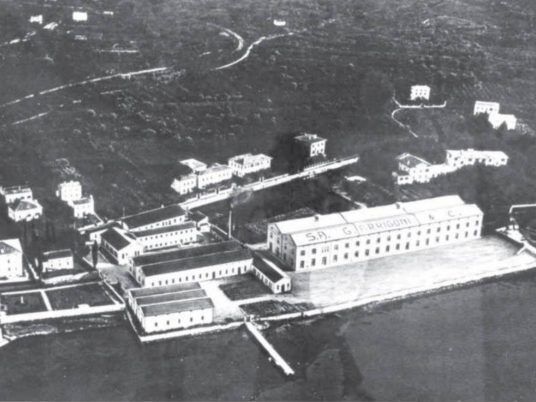

The beginning of fish processing and canning dates back to 1879 when Frenchman Emile Louis Roullet bought St Peter’s Church, its chapel and land close by on the cliffs in Izola; he also bought part of a beach in a small bay near Vascotto Baths and built the first fish processing and canning factory there and began operating on 20 January, 1881.

The factory was established by the General French Company for Canned Foods (Societe Generale Francaise). The locals named it “fabrica dei Francesi” or “fabrica dei bagni”. A second factory was built by Warhanek from Vienna and began operating on 22 December, 1882. Warhanek also built the first fish canning factory in the Gulf of Trieste in Duino near Trieste in 1867. Giovanni Degrassi built a smaller factory in 1882. Troion and some stockholder opened the fourth factory, S.I. Prodotti Alimentari Torrigiani, in 1904.The factories sold more than a half of their total production to foreign companies.

The factories fried, marinated and canned eel from the Venetian lagoon. They also produced fried and canned “Russian anchovies” in olive oil in 125g cans. The largest cans they offered included 1000g of anchovies. Salted anchovies from Norway were also cleaned, marinated in vinegar and spices and packed in small barrels.

THE SUCCESS OF THE CANNING INDUSTRY BEFORE WORLD WAR I

Factories produced plums, peas, beans, meat, tomatoes and salted and marinated fish during the dead season when full moon fishing was forbidden by law and when there was a lack of fish due to spawning’s natural oscillation. Management actively marketed their products, sending them to fairs worldwide, winning many awards and maintaining solid contacts with agents and clients. It became the main supplier for the Imperial Army. It exported to all of the countries of Europe, including Russia, the Near East and America.

The lack of raw materials and labour force during WWI paralyzed all of the industrial activities in the region. Production ceased completely in 1918 and the factory was closed until 1920. The region suffered poverty and famine, and this was then compounded by drought, the plague and the Spanish flu. The Adriatic Sea was full of drifting mines and net and night fishing were strictly forbidden; vessels had to stay in port during the night. Most of the able-bodied, young local men were on the front line and the older fishermen and the women who had previously worked in the factories were unemployed.

THE NEW RISE OF THE FACTORIES

The factory was modernized with new steam boilers, autoclaves, new working halls and electricity. The company owned a fleet of 29 vessels for fishing tuna and two transport ships for frozen fish. Product quality was extremely important. They produced fish and vegetable products, fish oil and marmalade.

The Italian company S.A. Conservatrici bought all of the Austrian bank’s property in Izola in 1920, then bought the Degrassi factory and S.I. Prodotti Alimetari Torrigiani. S.A. Conservatrici was restructured and renamed Ampelea Conservatrici S.A. in 1930. Meanwhile, Warhanek’s factory was taken over by Giorgio Sanguetti and renamed Arrigoni in 1926. Ampelea’s rise was rapid; it had strong support in Italy and aimed to please its market, but it accumulated foreign currency at the expense of its downtrodden labour force. Ampelea modernized its factory with new steam boilers, an autoclave for sterilization under pressure at 125°C, new working halls and electricity, and manufacture their products using anchovies, pilchards, mackerels, tuna and leerfish. They manufactured various canned products, including fish, fish meal, fish oil, boneless filets of imported fish, marmalade, vegetables, and tomato sauce and concentrate, and salty anchovy fillets in glass jars. Because of American and Canadian demand strictures, product quality was of utmost importance. The factory employed special tasters to ensure salted fish, fillet and pâté ripeness and quality until 1950, when its last taster hung up his cap. Ampelea and Arrigoni organized their own fishing fleet of 31 vessels in 1938, including Arrigoni’s vessels for fishing tuna and Ampelea’s two transport ships for importing frozen fish. After 1943, Slovenian territory was occupied by German troops who took sovereignty from the Italian Republic and incorporated it into the Third Reich.

DEVELOPMENT OF FISH PRODUCTS WITH VEGETABLES

During World War II, work was very limited and the company was left with only worn out machinery. This was followed by modernization. The company started preparing vegetable products, soup concentrates and tomato sauce. An excellent fish with vegetables in tomato sauce is developed.

When the war ended, the Regional Liberation Front took over the factories. Work was very limited due to political uncertainty, foreign ownership and lack of raw materials. In 1947, the central authorities in Belgrade issued an order to haul all of the modern machinery to Croatia because it was afraid that the peace treaty wouldn’t acknowledge this territory as part of Yugoslavia. In the same year, the factory was nationalized and renamed “Ex Ampelea”. The peace treaty assigned Izola to Zone B. The act of self-management made the company social property in 1950 and a year later it was being managed by a workers collective. Delamaris, the Import-Export company for fresh and canned fish, was established in 1952. Its final appropriation by Yugoslavia in 1954 marked a major turning point in the difficult post-war period. Modernization with the purchase of a new autoclave and canning machine followed. In 1956, the factory was named Iris and Arrigoni Argo. In 1959, the total reorganization of Yugoslavia’s food industry resulted in the merging of Iris, Argo, Delamaris, and Ikra from Koper (formerly de Langlade) to form the Combine of Can Industry Delamaris, which operated until 1973. The Iris plant processed fish and Argo processed other food products. The following three years, being full of reorganization attempts, were like a roller coaster ride for the company. The lack of domestic fish after 1962 resulted in product redirection to fruit and vegetable products, soup concentrates and, especially, mixed fish.

COMPANY REORGANIZATION

The following years were full of ups and downs, including mergers with other food companies to form HP Ljubljana, Droga Portorož and Holding Delamaris.

This final development resulted in our legendary fish pâtés. Delamaris was then transformed into a stock company and this was when we transitioned from wrapping paper to printed cans. omota na limenku s tiskom.

In 1973, Slovenia’s fish companies joined other similar companies to form the united company of the food industry under the name HP Ljubljana, which merged with Droga Portorož in 1978, working in this form until 1989.

KEEPING THE TRADITION

The company then tried to find new premises. It operated on rented land in Izola, became a limited liability company and produced its traditional recipes and other high quality products with no preservatives.

Slovenia’s independence diminished the size of its companies’ natural markets and forced them to redirect their energy to eastern and western foreign markets and face strong competition. Consequently, reorganization and increased productivity made possible by automation and manpower reduction followed. A business system for fishery and canned food was formed in January 1992. The principal holder was HOLDING DELAMARIS p.o. Izola. The system included the following companies: Delsar d.o.o. (can industry), Riba d.o.o. (fishing), Delmar d.o.o. (fish trading), Lera d.o.o. (fish farming) and Frigomar d.o.o. (frozen fish packing). Privatization was finalized in 1997 and four new companies were formed: Delamaris d.d., Delmar d.o.o., Riba d.o.o. and Frigomar d.o.o. In August 2008, the production division was separated from Delamaris, konzervna industrija d.d. (public limited company), and began functioning independently within Delamaris, konzervna industrija d.o.o. (abbreviated name: Delamaris d.o.o.).

RENOVATION INVESTMENT

Pivka perutninarstvo d.d. became the owner of Delamaris d.o.o. in December 2009 by purchasing it outright and began investing in production activity development and the Delamaris trademark to preserve jobs.

The company moved its production to a newly-built building close to Pivka in Kal in 2014. It is focused on sustainable development, uses aluminium packaging material, promotes traditional products and develops new ones.

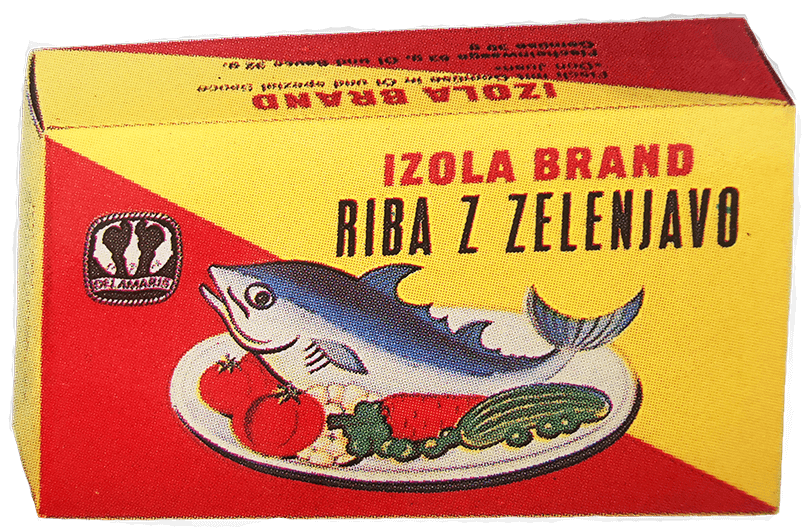

PACKAGING OVER TIME

Many people have used Delamaris products for their entire lives and its products are recognised by many generations.

Some product packaging has changed several times throughout the history of the company and differ according to market.

Delamaris products have a tradition and recipes that are more than 100 years old.